The line for sorting and palletizing of raw parquet boards.

We designed and made a robotized line for sorting and palletizing of raw parquet boards for Europarquet Sp. z o.o. company – the manufacturer of natural wood floors and wooden top tabels. The main demands of the application were:

- large dimensional variability of workpieces,

- low dimensional accuracy of workpieces supplied to the line,

- the need to sorting and palletizing a wide range of products,

- handling pallets with dimensions of 1800 x 1000mm,

- high efficiency parameters of the application.

The developed solutions allowed for implementation of the application in the assumed budget, while achieving quality and efficiency parameters of production.

The KUKA KR120 R3200 PA palletizing robot with a load capacity of 120kg and a range of over three meters was placed between two pallet carriers. It allowed for the set pick-up zone of board sets directly in front of the robot, optimizing cycle times for both pallets. Raw board are stacked by means of a customized system, based on roller conveyors and a vacuum system, mounted on the FESTO electric linear unit.

After sorting, sets of board are delivered by a belt conveyor to the pick-up section near robot head. On the station there is built-in automatic magazine of spacers and the head on robot enables the work with both parquet boards as well as spacers with the same vacuum gripper. Two independently driven pallet carriers enable the station to operate without interruptions during the pickup and loading of pallets.

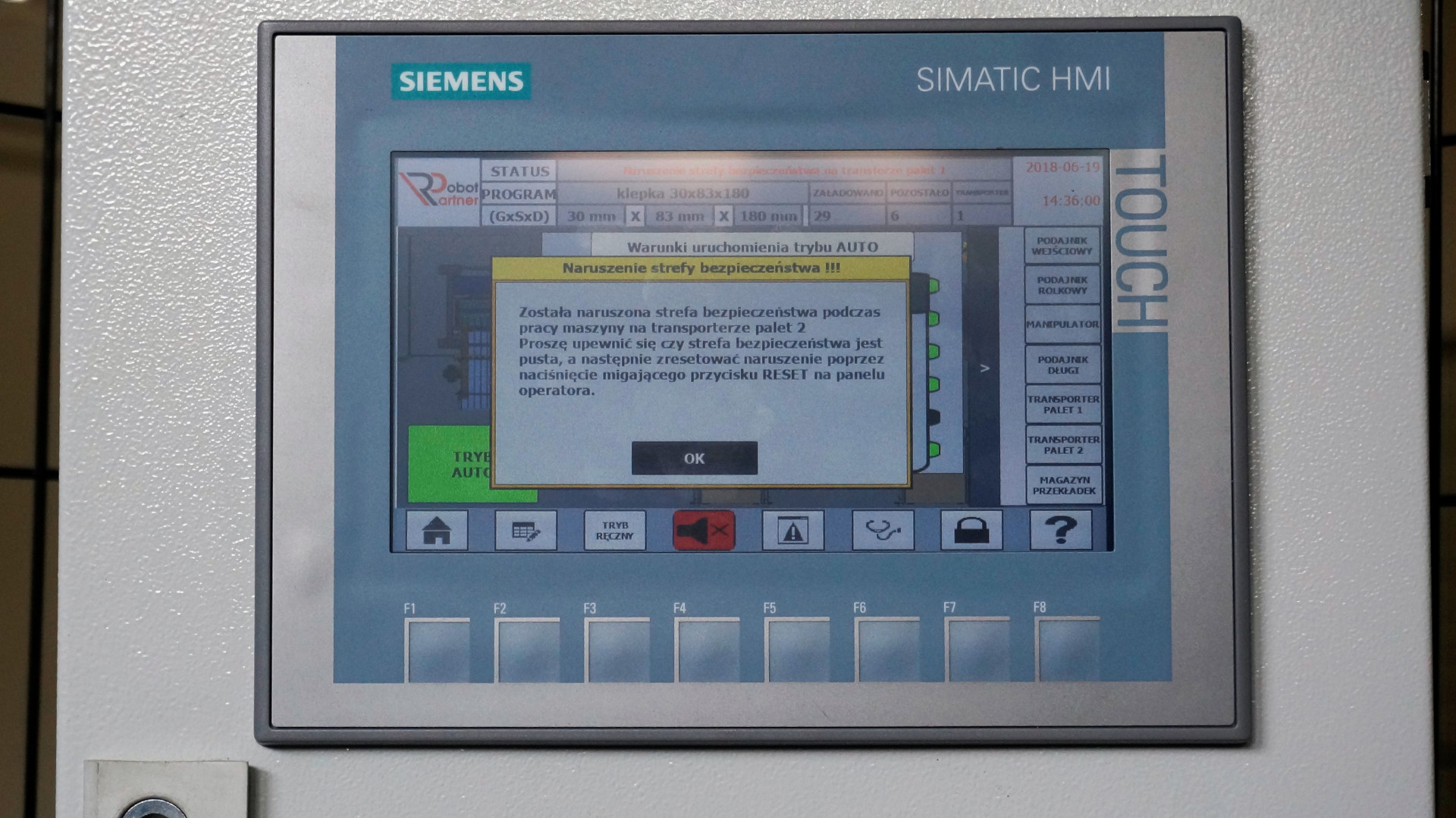

The whole station was guarded with a safety fence from Troax Polska company and secured with additional safety elements, which are supervised by the SamosPRO programmable controller from Wieland company.

The central control unit of the line is the Siemens S7-1500 PLC, equipped with the network interface and HMI graphic panel.

The automation of the process of raw board sorting and palletizing, at the possibility of working with a wide range of workpieces dimensions, allowed to achieve stable and countable production coefficients. Ensuring production efficiency allowed moving employees from the palletizing process to more demanding production tasks.

Previous Next