Accomplishment of workcell for roll forging with an industrial robot.

For Company Kuźnia Matrycowa in Lublin we have developed and manufacture a fully automated workcell for robotic roll forging. The assumptions of the application was based on several important requirements:

- eliminating blacksmith from roll forging process,

- ensuring synchronization with rotary tools of the roll forging machine,

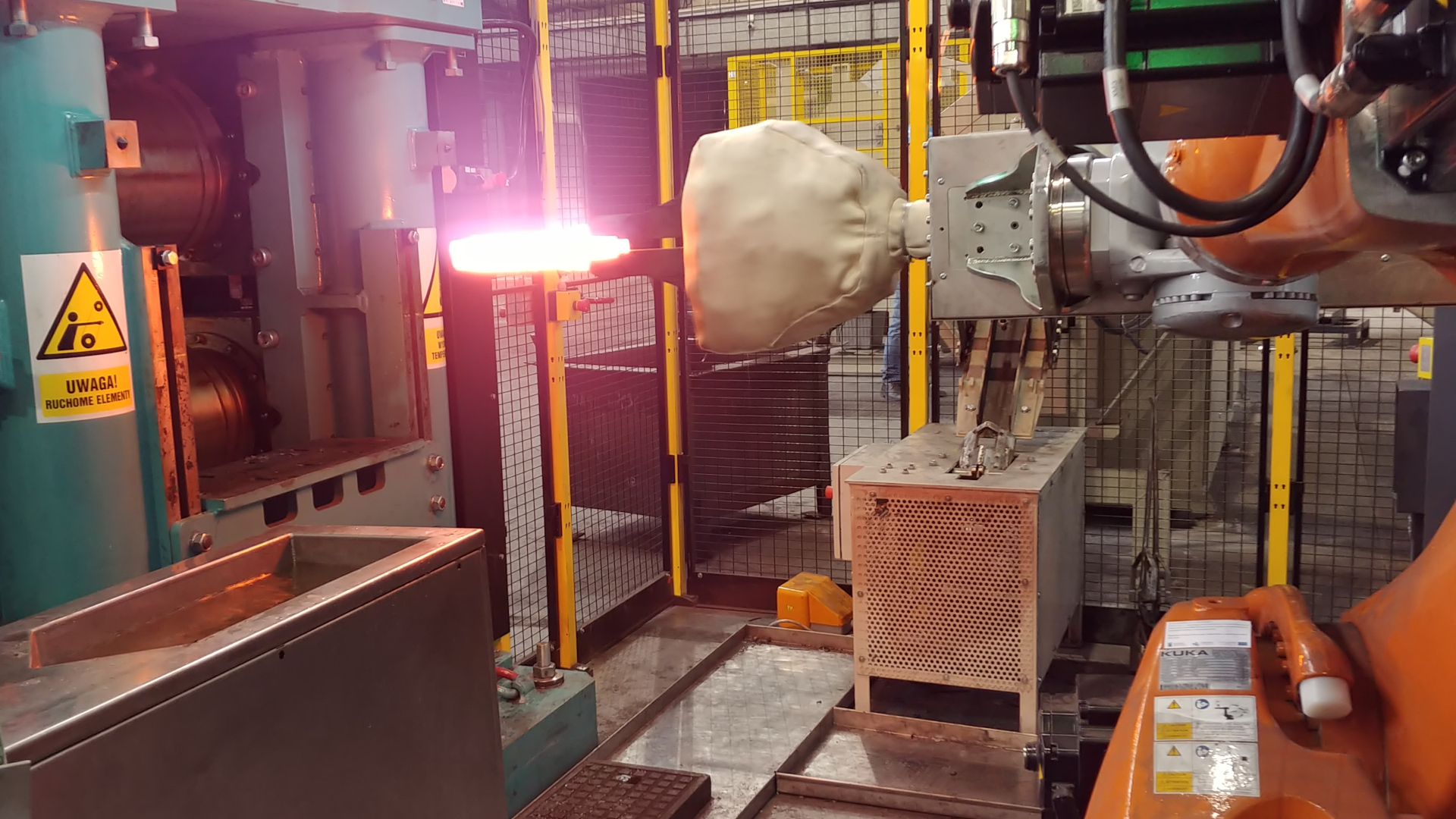

- collecting raw rods from an induction furnace heated up to 1300 degrees Celsius,

- ensuring the safety of machines during their synchronized work in the process,

- the possibilities of conducting tests in manual mode.

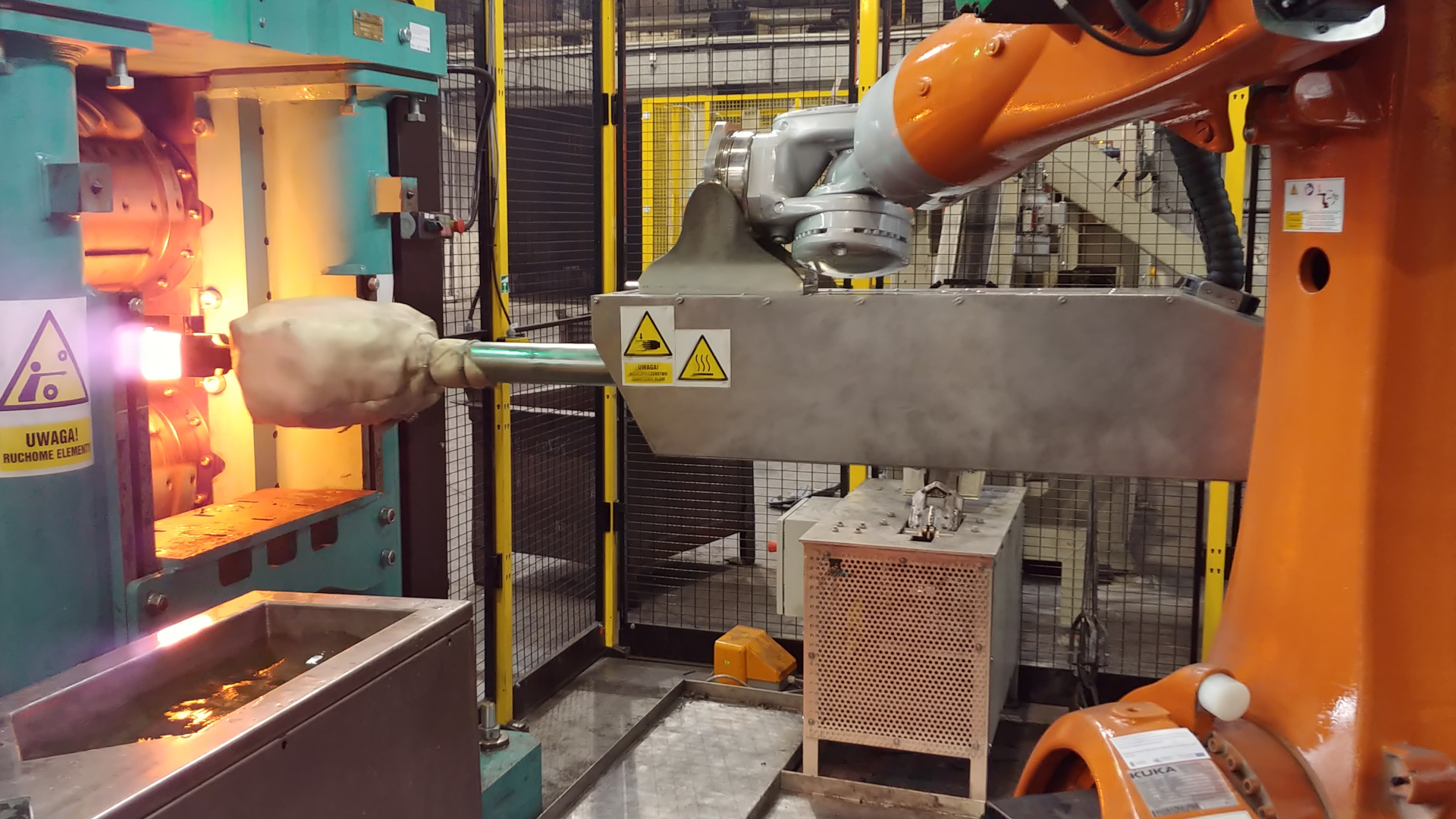

In the application we used the KUKA industrial robot from the Quantec series. We chose a dedicated version of the “Foundry” robot, because the entire application was to work in the harsh environment of an industrial forging. Importantly, this version is dedicated for the foundry, forging industry and environment with harsh ambient conditions and increased temperature.

Our engineering team have developed a customized working head, adapted to continuous work with workpieces at a temperature exceeding 1300 degrees. In addition, the head drive ensures precise handling of workpieces to the tool on roll forging machine and protects both the robot and the machine against the effects of emergency stops or desynchronization.

Another important issue was the safety of operators and blacksmiths working in the vicinity of the rolling station. The enclose entire zone with a safety fence equipped with ergonomic access from both sides of the robot. Moreover whole safety system is flexible by use of a programmable safety controller.

Summarizing, through the automation of the roll forging process, we achieved repeatability in the production of semi-finished products. Due to the elimination of manual work of the blacksmith, a constant process efficiency factor was achieved. Undoubtedly, robotization of the roll forging machines increases the level of safety of the whole production process. In summary, the automation of forging processes has a positive effect on all aspects of the production of forged components.

Previous Next