SPECIAL MACHINES

Having qualified staff and necessary tools, we offer:

\ manufacture of production machines and equipment,

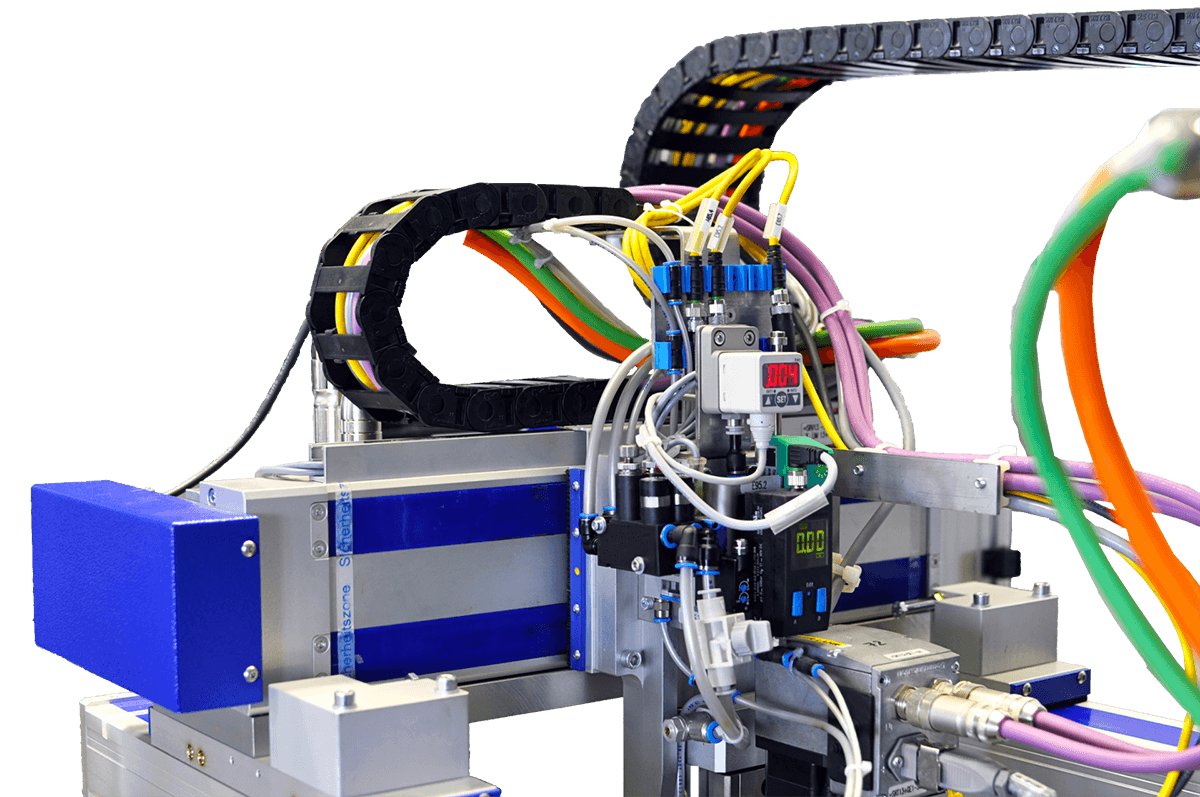

\ design of automation and pneumatics systems,

\ audits and modernization of machines safety,

\ programming of industrial robots,

\ design of mechanical construction and parts,

\ periodic electric measurements of machines and devices.

We comprehensively support our clients both in the creation and modernization of production processes.

AND MODERNIZATIONS:

We offer:

\ technical audit and machine safety audit,

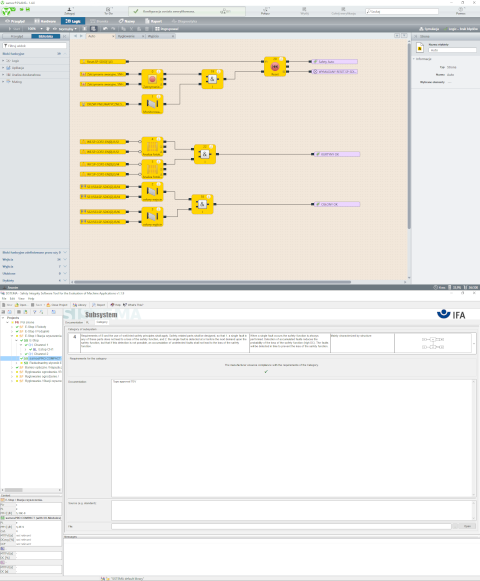

\ risk assessment in accordance with PN-EN ISO 12100 standard,

\ assessing the possibilities and potential for improving safety,

\ reconstruction of the machine in accordance with the described documentation,

\ machine validation for compliance with CE,

\ issuing a declaration of conformity of the machine with the CE mark.

We carry out risk assessment in accordance with the PN-EN ISO 12100 standard using the indicator method. Calculations of safety systems are made in dedicated software.

AND PROGRAMMING

We offer:

\ designs of mechanical systems and constructions in 3D CAD software,

\ electrical projects and automation systems in dedicated design software,

\ designs of pneumatic systems,

\ programming and reprogramming services of industrial robots,

\ programming PLC controllers and HMI panels of various companies (SIEMENS, Beckhoff, Mitsubishi and others),

\ reconstruction of machine systems and adaptation to new application requirements.

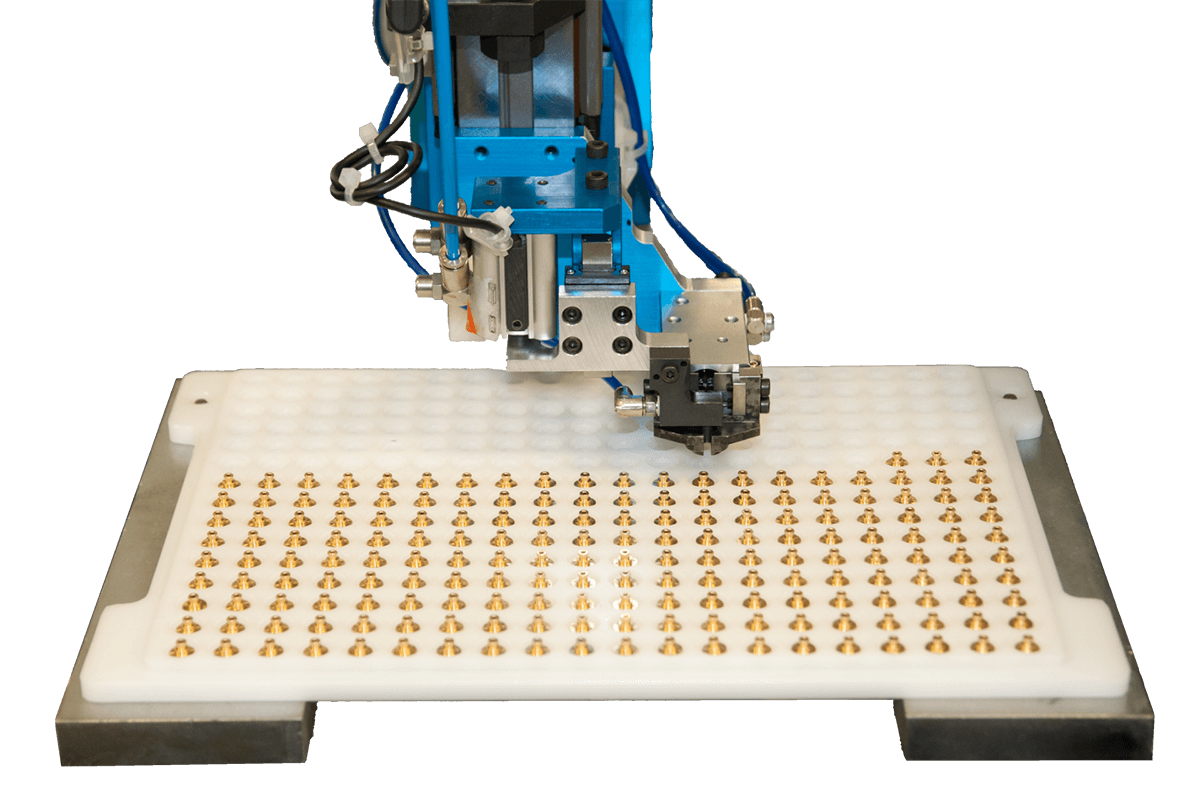

We adapt elements of grippers and working heads, as well as equip work stations with completely new solutions, allowing to achieve planned capacities with production accuracy.

We replace worn elements of automation systems, pneumatics and machine mechanics, so that as a result of works carried out a modernized or adapted machine meets the requirements of trouble-free operation over the next years of work.

We modernize or re-develop algorithms of PLC controllers, HMI desktops, industrial robots and security systems. In addition, we adapt safety equipment to current legal and application requirements.

WELDING:

Having the right equipment and experience, we make constructions and components welded from technical plastics.

By means of an extruder and manual welding machine we are able to produce small and large-size components from materials such as:

\ PE,

\ PP,

\ PVC,

\ other weldable.

For production purposes, we use materials from the world's best producers and distributors of plastics. We manufacture designed systems and assemblies based on standard commercial elements, i.e.

\ plates,

\ pipes,

\ fittings,

\ armature, subjected to individual treatment and matching to customer requirements.

Dedicated handling systems will be good solution in places and applications where installation and operation of the robot is very difficult or impossible due to the footprint or avalible mounting conditions.

Individually developed 3 and 4 axis manipulators also work well in budget applications. Especially in places where, compared to full 6-axis industrial robot kinematics, it does not increase investment outlays.