WELDING ROBOTS

We offer our clients comprehensive robotization and automation of welding processes, developed on the basis of:

\ workpieces technical documentation ,

\ analysis of physical workpieces,

\ WPS technology cards,

\ implemented manual welding technologies.

We develop, perform and implement automatic welding stations and robotized cells for MIG/MAG processes, TIG processes, high-performance welding as well as special processes such as CMT or WAAM.

ROBOTIC WELDING

\ High efficiency and speed of welding - robot repeatability is ±0,04mm and maximum robot linear speed up to 2m/s.

\ Very good quality and high aesthetics of welds.

\ Welding versatility - the robot program can be adapted for various workpieces within one work station.

\ The possibility of welding at high current without harmful effects on employees.

\ Possibility to implement welding technologies that are problematic for manual processes.

\ Limited need for quality control of seams and workpieces.

\ Reducing the number of defective or damaged workpieces.

\ Increasing the usage rate of welding equipment.

\ Limiting the possibility of damages and the number of services for welding equipment.

PROCESES

\ MIG/MAG welding - offers high speed welding ensuring stable penetration, meets all basic requirements for precision and performance.

\ High performance welding - offers higher wire feed speeds and melting performance compared to the standard system, requires the arrangement of two sources and welding packages on one robot.

\ TIG welding- offers the highest quality and perfect look of seams, allows to achie twice the efficiency in compariosion to manual TIG welding.

\ Plasma welding – possible to achiev high welding speed and deeper penetration, especially when welding elements with a thickness of up to 8mm.

\ Cold Metal Transfer CMT - allows for welding thin sheets with a very small amount of heat transferred to the material with an extremely stable arc, also useful when welding galvanized elements and combining different materials.

\ Spot welding - a welding method used especially during sheet metal joining processes and workpieces welding preparation.

Welding robotization have a direct impact on the benefits achieved by end user. The biggest advantages of welding automation are both, increase of production efficiency and higher quality of manufactured products.

Welding with robotic arm increases the quality and repeatability of seams. The welding robots providing much better control over seams also ensuring constant penetration with parent material..

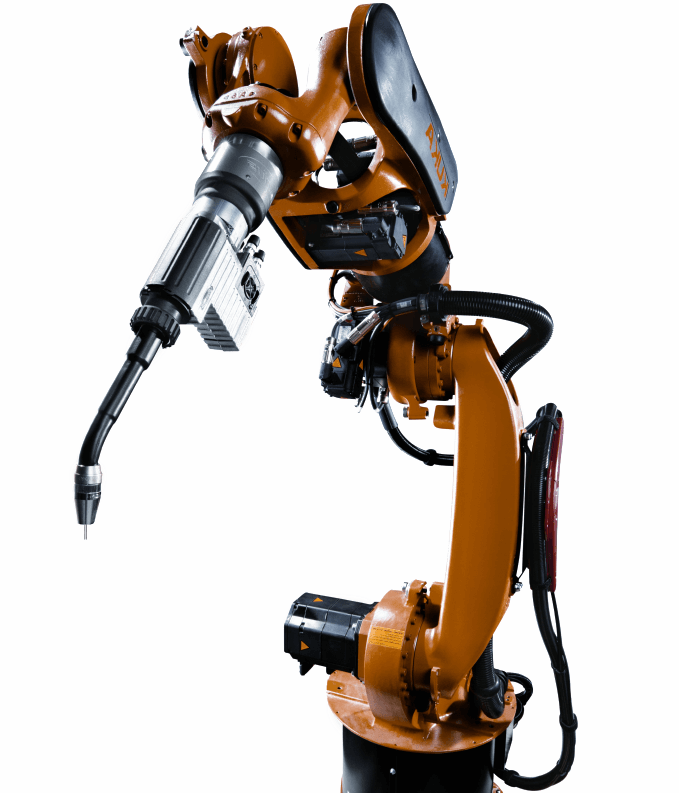

Robotization of welding is based on an appropriately selected industral robot and high-class welding equipment. Welding equipment for robotization consists of several basic elements. The power source with communication interface allows for continuous cooperation with the robot controller and gives the opportunity to use its full potential. The proper welding torch, thanks to the selected geometry, reaches welding positions even in hard to get places. The wire feeder ensures stable material feeding to the weld pool. The torch cleaning station with wire cutting unit ensures condition of the nozzle and contact tip, providing the stabel gas shield and the repeatable TCP for wire end.

The welding robot, working with dedicated welding fixtures, is responsible for making welds along with programmed trajectories. By using auxiliary axes, such as welding positioner or linear units, it is possible to weld the workpiece in one fixing. Such operations are often problematic or even impossible to perform during manual welding (due to limited access and the lack of visual inspection of the seam during the process).

WELDING CELLS

Standard robotized welding cells consist of:

\ one or two welding robots with stationary assembly or working on linear units,

\ the dedicated set of welding fixtures,

\ one or two welding positioners (single-axis, tilt-rotary, three-axis H-type or K-type),

\ welding source for the chosen method MIG/MAG, TIG or other,

\ welding torch cleaning station with wire cutting unit,

\ wire feeder working with a wire spool or barrel ,

\ welding safety fence with auxiliary safety devices (safety curtains, safety scanners, interlocking, e-stop buttons etc.),

\ ventilation system with extraction and filter for high levels of smoke and fumes ,

\ control panel, connected to the master control system.

Welding sources for robotic applications, combined with the capabilities of a industrial robot, allow to implementnew technologies and processes unavailable for manual welding. Basic MIG/MAG welding is still the most popular. In welding robotization applications with TIG, CMT processes and braze welding more and more common on the market. Laser and plasma welding also appears in factories. The welding robot open possibilities for high-performance welding, e.g. TWIN technology with two torches, working simultaneously in one seam

Welding robotization requires also aspects of environment preparing around a robotized cell. A ventilation system with extraction and filtering , shielding gas supply system, daily and periodic maintenance service system, and last but not least in the era of industry 4.0, also welding data logging and remote support.

A robotized welding station is also an obligation to ensure work safety for everyday operation and robot programming. Dedicated safety fences, full plate covers and welding viewfinders provide comfort and safety for workers.

In general opinion welding robot combined with a modern welding source provides all technical advantages in fabrication, also shows modern approach to welding. The robotization of the welding process I a way to stands out among other companies with production capabilities and the quality of manufactured products.