A line for semi-automatic glazing using an industrial robot.

We made a robotized line for immersion glazing of porcelite products for the AVANT Porcelite Factory. The main technical challenges in the application were primarily:

- the necessity of positioning a wide spectrum of workpieces for collection with a robot,

- the possibility of verifying workpieces before and after the glazing process,

- implementation of a dedicated head for immersion in enamel,

- technological aspects of the glazing immersion process.

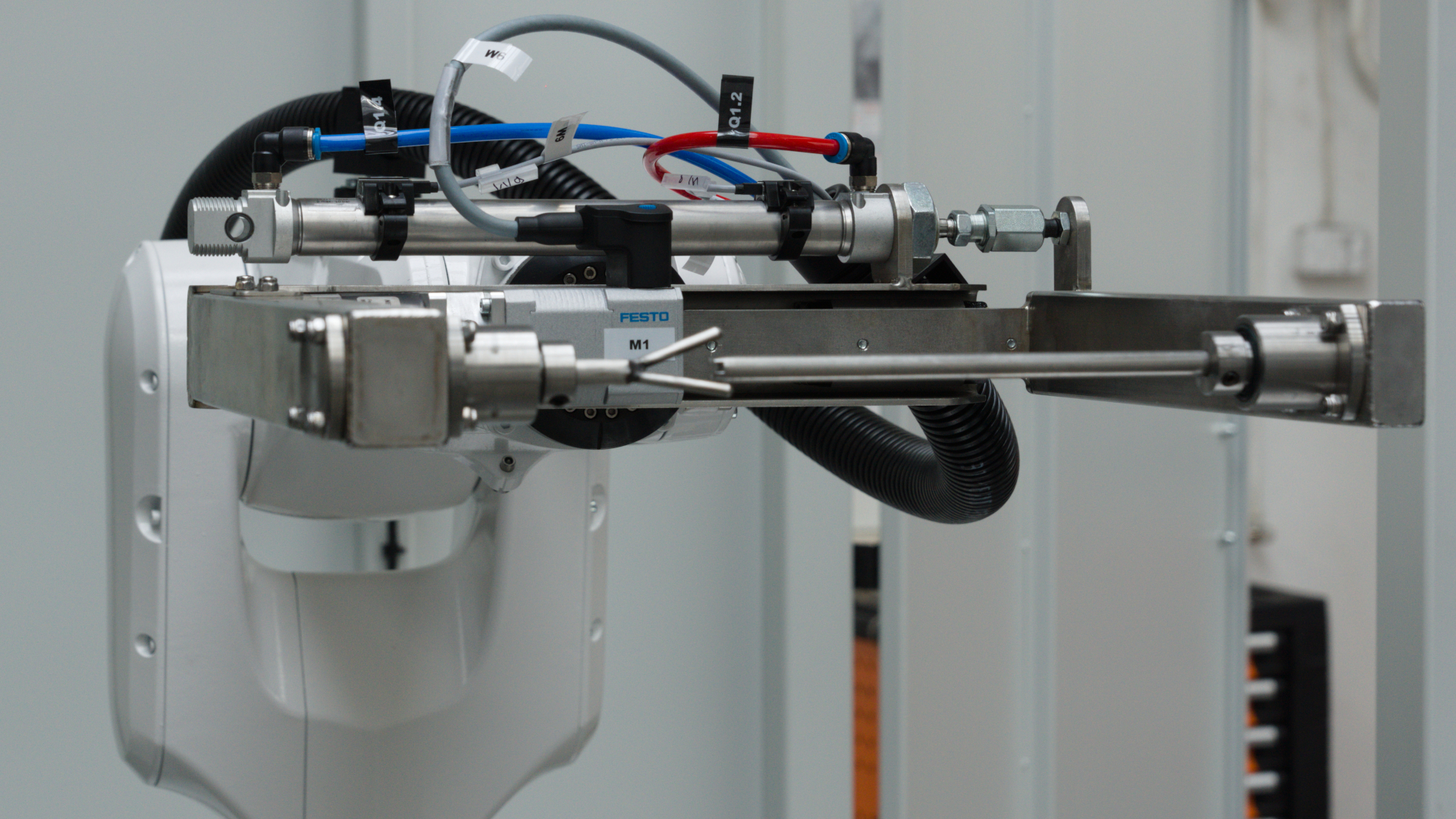

We integrated the Agilus series KUKA industrial robot into the application. Our engineers designed a electro-pneumatic head dedicated for workpieces. Process tanks were made of technical PVC by extruder welding technology. The machine has two sets of tanks, both of which have the option of quick color change, what’s more, they are also easy to clean. The continuous enamel mixing system ensures homogeneity of the mixture, which is important for the proper conduct of the process. Input and output storages ensure positioning of a wide spectrum of processed workpieces.

We designed the line taking into account the principles of ergonomics and work safety. In addition, we build up the process part with customized housing and also we equipped it with the necessary additional safety elements.

The automation of the process allowed to achieve repeatability of operations of particular workpieces, which directly affects the quality and uniformity of the coating. Moreover, the automation of the process allowed to determine efficiency factors for each of the processed workpieces, as well as to verify and improve materials management.

Previous Next